Lithium Battery Configurations

A secondary lithium battery functions like other primary batteries, powering devices through discharging and then recharging for reuse. For a full comparison between SLA (sealed lead acid) and lithium batteries, see our detailed guide. This blog explores lithium cells, their configurations, and their practical applications, and explains how lithium battery construction optimizes performance for specific uses.

LITHIUM CELL FORM FACTOR

When you take off the top of a lithium battery pack, you’ll first notice the individual cells. There is also a circuit board of some kind. There are three types of cells used in lithium batteries: cylindrical, prismatic, and pouch cells. For the purpose of this blog, all cells are lithium iron phosphate (LiFePO4) and 3.2 volts (V).

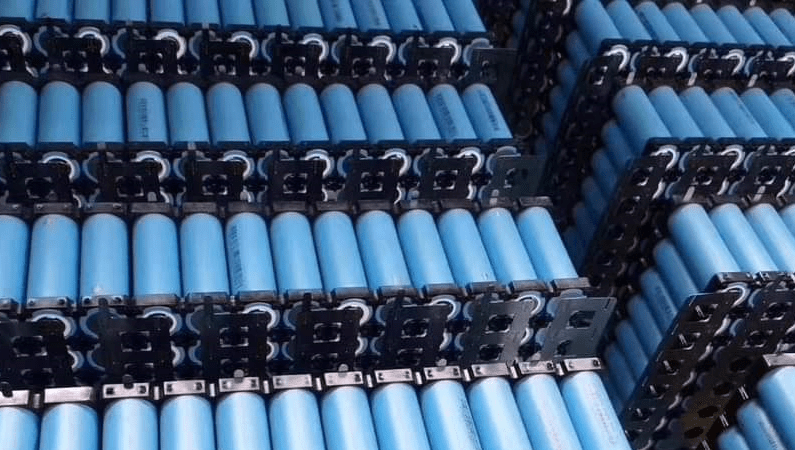

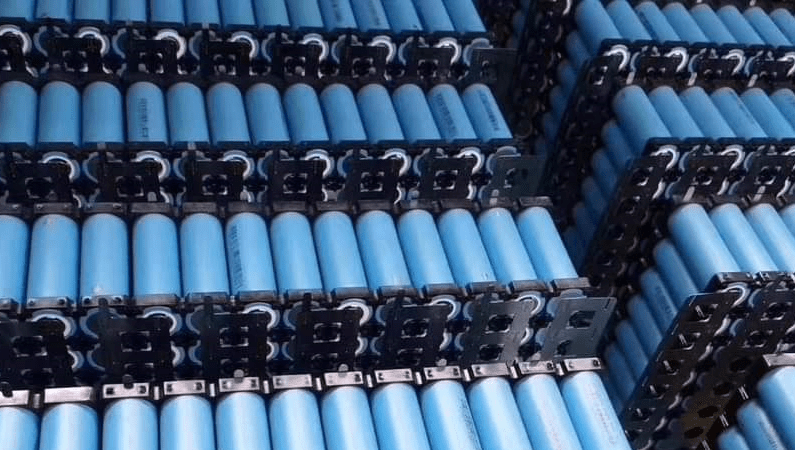

CYLINDRICAL LITHIUM CELLS

Cylindrical cells, inspired by traditional AA batteries, come in various sizes and amp-hours as energy or power cells. They suit both large and small battery packs but excel in smaller Ah applications like power tools, drones, toys, and medical equipment, where space and weight are critical.

PRISMATIC LITHIUM CELLS

Prismatic cells get their name from their rectangular shape, which fits square battery compartments. Common in laptops and energy storage devices, they offer higher capacity than cylindrical cells by packing more lithium per volume. Their larger size supports bigger battery packs and single-cell setups, making them ideal for power and energy applications, including SLA replacements.

LITHIUM POUCH CELLS

Power-Sonic’s non-powersport lithium batteries use prismatic or cylindrical cells, while the Hyper Sport Pro line features pouch cells. A pouch cell is an aluminum foil pouch containing lithium iron phosphate polymer with two terminal tabs. Its design maximizes lithium volume, fits directly into applications without a case, and delivers higher power density than other cell types.

TYPES OF LITHIUM CELLS

In addition to the lithium cell form factor, you will also need to decide if you need a lithium power cell or a lithium energy cell. A power cell is, you guessed it, designed to deliver high power. Likewise, an energy cell is designed to deliver high energy. But what exactly does that mean and how are lithium power cells and energy cells different?

WHAT IS THE DIFFERENCE BETWEEN A POWER CELL AND AN ENERGY CELL?

First, note that all types of cells cycle, but the depth and speed vary (see battery C ratings). Power cells deliver high current loads over short, intermittent periods, making them ideal for high-rate starter applications or power tools that generate high loads and torque. Energy cells provide sustained, continuous current over long periods, making them suitable for motive cyclic applications like scooters and e-bikes. All lithium cells handle cyclic use—even power cells—but cycle length differs. For example, a power tool user expects the tool to run about an hour before charging, whereas a scooter user would be dissatisfied if the vehicle ran out of power after only one hour.

HOW TO CONFIGURE A LITHIUM PACK (BATTERY)

When building a lithium battery, first select the cell type, then determine the required amp-hours, voltage, and amperage. For example, a 25 AH 3.2 V prismatic cell can form a 125 AH 12.8 V battery in a 4S5P configuration, where parallel connections boost capacity and series connections increase voltage.

Different cell form factors—cylindrical, prismatic, or pouch—offer flexibility in size, shape, capacity, and voltage, allowing you to tailor the battery to your specific needs.

When selecting lithium cells, consider the application. Power cells provide higher output for starter batteries, and using a battery outside its intended purpose shortens its lifespan. The PSL-FP line offers power and energy cells in prismatic and cylindrical forms for customizable high-rate, high-capacity, or deep-cycle applications.

Building a lithium battery requires considering the intended use, physical size, voltage, and amp-hour requirements. Understanding these configuration options ensures you create a better battery. Contact us with any questions.